fastCHECK

1-Click 3D fastener flushness measurement

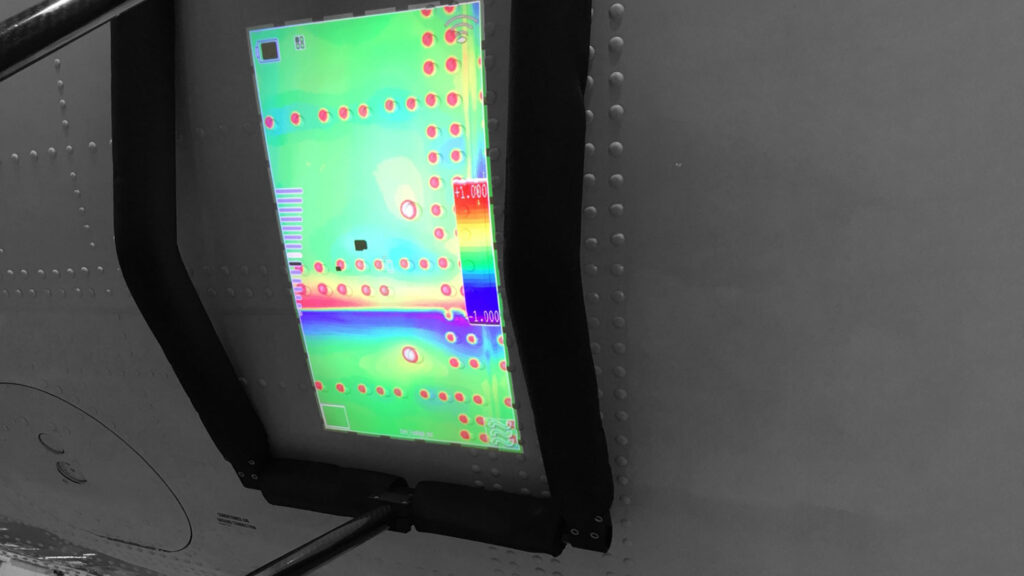

Optimized for the aerospace industry, fastCHECK measures fastener flushness quickly, consistently, and objectively. Empower your operator with instant “go/no-go” results for improved quality control.

Where is it used?

- Main Components Assembly

- Final Assembly Line

- Quality Control / Assurance and more

What can it measure?

- Flushness

- Angle

- Rivet Pull-In

- Pitch

The right tool for the job

- Inspect 100 fasteners or more in one click within seconds.

- Instant go/no-go results projected on the surface.

- Lightweight, compact, battery-powered.

- Easily customizable to your preferred fasteners (and tolerances).

- Measurement uncertainty as low as 0.012 mm / 0.0005″.

(ISO17025 accredited)

KEY FEATURES

- Simplicity: Designed to be used by operators of all skill levels. Use it like a camera: One click and view the results within seconds!

- ISO17025-proven Accuracy: Measurement uncertainty is as low as 0.012mm / 0.0005″. The operator can verify performance at any time.

- Connected Device: LTE, WiFi and USB connectivity.

- Portability: Handheld, battery-powered device to be used by human operators or in robotic automation cells.

If you are interested in this product, please contact us!